Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

Introduction to Fault Diagnosis (Part 1): What Exactly Is Vibration, and Why Can It Reveal Faults?

What exactly is vibration, and why can it reveal faults?

In the various machinery and equipment we encounter daily—motors, fans, pumps, compressors, turbines...—almost all devices exhibit a slight tremor during operation.

This “tremor” is, in fact, vibration.

But before diving into troubleshooting, we need to first understand two more fundamental issues:

What exactly is vibration?

Why does it indicate whether equipment is healthy?

1.What is Vibration?

Vibration is everywhere. It exists not only in mechanical equipment but also pervades nature and our daily lives.

1)Vibrations in Nature

For example:

Tree branches swaying back and forth in the wind;

The ground rising and falling during an earthquake;

Air molecules vibrating in place as sound propagates;

A hummingbird's wings beating rapidly back and forth during flight.

Figure 1: Wings flapping rapidly back and forth

These phenomena are essentially processes in which objects repeatedly oscillate around a certain equilibrium position.

2)Vibrations in Daily Life

In our daily lives, we frequently encounter vibrations:

The vibration of a phone ringing;

The shaking of a washing machine during the spin cycle;

The jolting of a vehicle over potholed roads;

The swaying motion of a swing as it moves back and forth;

The vibration of a plucked guitar string as it produces sound.

Figure 2: Vibration and Sound Production After the String is Plucked

These are all manifestations of vibration in daily life.

3)Vibration in Mechanical Equipment

Mechanical equipment consists of various rotating and moving components, such as motor rotors, bearings, gears, and couplings.

During operation, these components experience rotational inertia, friction, eccentricity, or assembly errors, leading to periodic shaking—this is mechanical vibration.

When equipment runs smoothly, vibrations are regular and minimal;

However, issues like component wear, imbalance, or misalignment cause vibration characteristics to change.

This is precisely the crucial basis for our fault diagnosis.

2.Vibration is not inherently bad, but excessive vibration is dangerous.

Vibration itself is a natural phenomenon and does not necessarily indicate equipment malfunction.

Regular, minor vibrations are a “sign of health,” while irregular, major vibrations are a “distress signal.”

However, if vibration becomes uncontrolled, it can lead to a series of hazards:

Noise pollution: Structural resonance generates noise, affecting the operating environment.

Figure 3:Noise Pollution Caused by Vibration

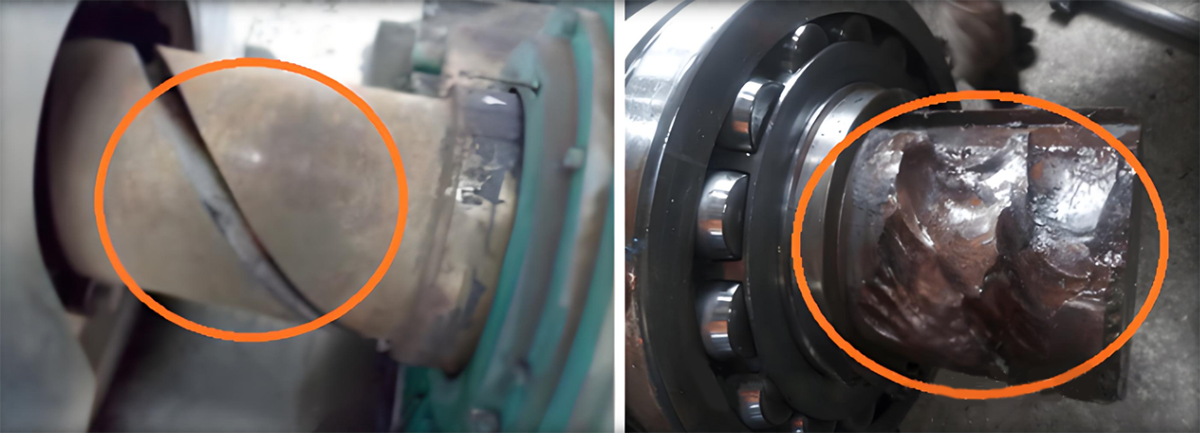

Equipment Damage: Prolonged vibration can cause bolt loosening, bearing wear, and crack propagation.

Figure 4:Equipment Damage Caused by Vibration

Production Shutdown: Severe vibration can trigger shutdowns for maintenance, resulting in economic losses.

Safety Incidents: High-speed equipment may experience flying components or structural failure due to vibration.

Therefore, the significance of vibration monitoring lies in:

Detecting anomalies before failures occur, preventing problems before they arise.

3. How to Describe a “Vibration”?

To analyze vibrations, we need to characterize them using several physical quantities:

Parameters | Meaning | Simply put |

Amplitude | Maximum distance from the equilibrium position | How much does it shake? |

Frequency | Number of vibrations per second | How fast does it shake? |

Phase | Time difference of the vibration waveform relative to the reference point | Who moves first, who moves later |

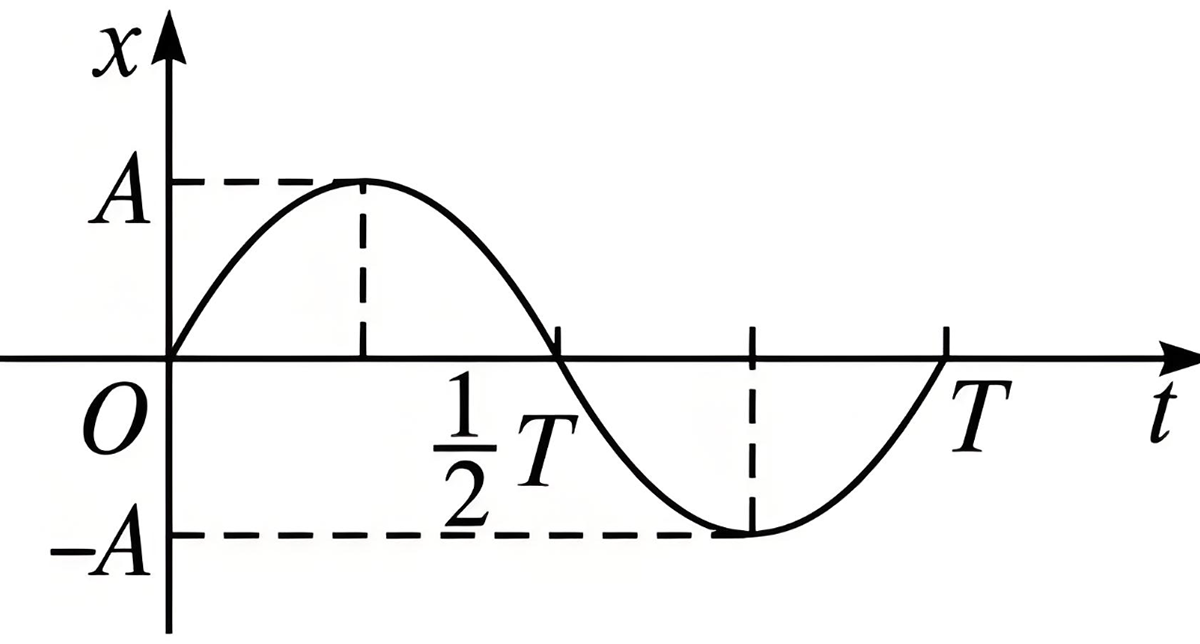

The most common type of ideal vibration is called simple harmonic motion, mathematically expressed as:

y = A·sin(2πft + φ)

Where: A is the amplitude, f is the frequency, and φ is the phase.

Figure 5 Sine Wave: Simple harmonic motion with amplitude A, frequency 1/T, and phase 0.

Although the vibration of real equipment is more complex than this, it can be regarded as the result of many simple harmonic motions superimposed.

4.Three Manifestations of Vibration: Displacement, Velocity, Acceleration

When measuring vibration, we typically use three physical quantities to represent its intensity:

Form of expression | Physical meaning | Common Scenarios |

Displacement | Distance deviating from the original position during vibration | Low-frequency, high-amplitude vibration, such as imbalance or misalignment |

Velocity | Reflecting the speed of vibration changes | Commonly used in the mid-frequency range, it is the most frequently employed indicator. |

Acceleration | Indicates the rate of change in velocity, reflecting impact-induced vibration. | High-frequency and impact-related faults, such as bearing and gear issues |

The relationship among the three is as follows:

Velocity = Displacement × Angular Frequency

Acceleration = Displacement × Angular Frequency²

Higher frequencies result in greater acceleration, which is why accelerometers are often used for detecting high-frequency faults.

5. Vibration Diagnostics: Making Machines “Speak”

When equipment malfunctions, the frequency, amplitude, and waveform of vibration signals change.

By installing vibration sensors, collecting signals, and analyzing their spectrum, we can determine:

A spike at a specific frequency: May indicate rotor imbalance.

Noise in the high-frequency range: May indicate bearing damage.

The presence of harmonic signals: May indicate misalignment or looseness.

This is the core of vibration fault diagnosis:

Let the equipment itself tell us where the problem lies.

In today's article, we explored the fundamental concept of “vibration”—not merely a physical phenomenon, but the language of equipment health.

To truly “understand” the voice of machinery, one must learn how to collect and analyze vibration signals. Next time, we'll guide you through the first step in vibration diagnostics:

How Are Vibration Signals Collected? — An Introduction to Sensors, Sampling, and Measurement Point Layout

Yangzhou Xiyuan Electronic Technology Co.,Ltd.

#77 Yeqiao Road, Liandong U Valley slender West Lake Innovation port, building 10-2,Hanjiang District, Yangzhou,Jiangsu,China

Mobie Phone: +86 180-5105-8377

Tel: +86 514-82885589

Whatsapp:+86 182-6066-6867

Email: sale1@yzxyt.com

Fax: +86 514-82885089