Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

How to Identify Faults Such as Imbalance, Misalignment, Looseness, Wear, and Resonance? A Quick Guide to Vibration Spectrum Characteristics for 25 Types of Equipment Faults

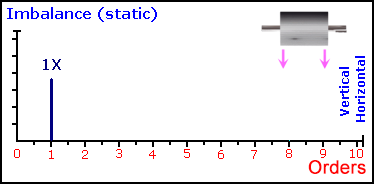

1.Static imbalance

Characteristics: Radial 1X peak (vertical or horizontal direction).

If the machine becomes unbalanced, we obtain a sinusoidal time-domain waveform with a frequency equal to the rotational speed, featuring a prominent peak at the rotational speed frequency (1X). The simplest unbalanced model simplifies the rotating shaft's center of gravity to a single point. This imbalance is termed static imbalance because it manifests even when the rotating body is stationary. If placed in a frictionless bearing, the center of gravity will automatically rotate to the lowest position. Static imbalance generates a 1X frequency force on both bearing supports of the rotating shaft, with the force direction always identical at both bearings. Vibration signals collected from these two bearings are in phase.

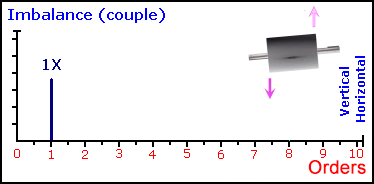

2.Imbalance

Characteristics: Radial 1X peak (in the vertical or horizontal direction).

If the machine exhibits imbalance, we will obtain a sinusoidal time-domain waveform with a frequency equal to the rotational speed. The spectrum will show a prominent peak at the rotational speed frequency (1X). A rotating body with an even imbalance may achieve static balance (the body appears perfectly balanced when placed on frictionless bearings). However, when the body rotates, centrifugal forces act on its two supporting bearings, and these forces are out of phase (opposite in direction).

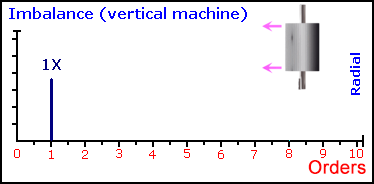

3. Vertical installation of rotor imbalance

Characteristics: Radial 1X peak (horizontal direction)

When measured radially (horizontal or tangential direction), the spectrum will again display a peak at the first harmonic (1X). To isolate motor imbalance from pump imbalance, it may be necessary to disassemble the two components, rotate the motor separately, and examine its 1X spectrum. If the amplitude at 1X remains high, the fault lies with the motor; otherwise, the fault originates from the pump.

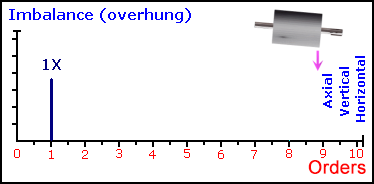

4.Unbalance in the cantilever rotor

Characteristics: High-amplitude 1X peaks in both axial and radial directions (vertical or horizontal orientation).

In externally suspended or cantilevered machinery, high-amplitude 1X vibration can be detected in the horizontal, vertical, and axial directions. We can detect high-amplitude 1X vibration because imbalance causes shaft deflection, resulting in axial displacement of the bearing housing. Common suspended rotating components include short-coupled pumps, axial-flow fans, and small turbines. (Phase instability) Note: Distinguish from bearing misalignment.

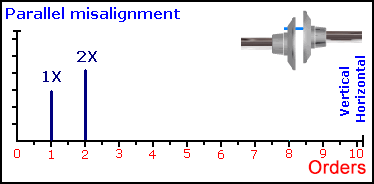

5.Parallel misalignment

Characteristics: Radial 2X peak, radial 1X low-amplitude peak (in vertical or horizontal direction).

Misalignment where shaft centerlines are parallel but not collinear is termed parallel misalignment (or offset misalignment). Parallel misalignment generates shear stress and bending deformation at the coupling ends of each shaft. Bearings at both ends of the coupling generate high-intensity 1X and 2X vibrations radially (both vertically and horizontally). In most cases, the amplitude at 2X is higher than at 1X. For pure parallel misalignment, the amplitudes at 1X and 2X in the axial direction are both small. Vibrations detected along the coupling exhibit phase differences in the axial and radial directions, with a 180-degree phase shift in the axial direction.

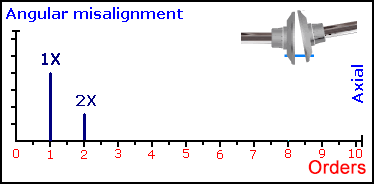

6.Misalignment

Characteristics: Axial 1X peak, axial 2X low-amplitude peak, radial 1X low-amplitude peak.

When two misaligned shafts intersect at a point but are not parallel to each other, this misalignment is termed angular shaft misalignment. Angular shaft misalignment induces a bending force on the shaft, appearing in the spectrum as high-intensity 1X vibration and minor axial 2X vibration at both bearing ends. Significant radial (horizontal and vertical) 1X and 2X vibrations will also be present, but these vibrations are in phase. The vibrations exhibit a 180-degree phase difference in the axial direction while being in phase radially.

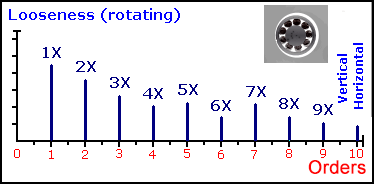

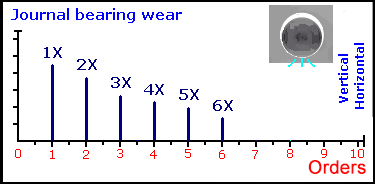

7.Loose rotating components

Characteristics: Radial 1X harmonic (0.5X harmonic may occur in severe cases)

Excessive clearance between the journal (sleeve) and rolling bearing (bearing looseness) generates 1X harmonic, which can sometimes extend up to 10X. Excessive clearance in sliding bearings may generate 0.5X harmonics as shown later. These are commonly referred to as half-order components or subharmonics. The primary cause is friction or severe impact forces, which can occasionally produce 1/3-order harmonics. This is mainly attributed to improper component installation.

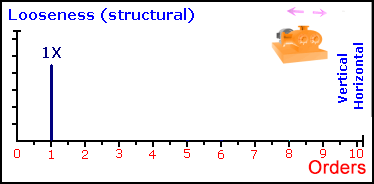

8. Structural Looseness

Characteristics: 1X peak in the horizontal direction.

Looseness between the machine and its foundation causes 1X vibration at points of weaker rigidity. This typically occurs horizontally but may vary depending on actual conditions. Severe looseness often generates low-order 1X harmonics. It is difficult to distinguish between imbalance, foundation looseness, or flexibility, especially in vertically mounted machines. If the amplitude of the horizontal 1X vibration is significantly greater than that of the vertical 1X vibration, it is likely caused by looseness. If the amplitude of the horizontal 1X vibration is smaller than or equal to that of the vertical 1X vibration, imbalance is more probable. Looseness or flexibility in the foundation results from loosened, corroded, or cracked bolts in the fastening connections. Note: If the machine foundation exhibits high elasticity, horizontal axial vibration will be significantly stronger. In such cases, phase difference can serve as an auxiliary identification method: the vertical vibration phase difference between the machine and foundation will be 180 degrees. (This type of vibration, caused by loosening of anchor bolts, base plates, or grout, produces 1X frequency vibration.)

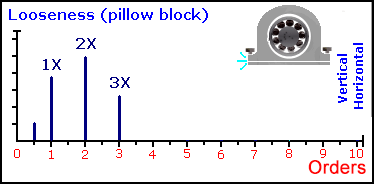

9.Loose bearing housing

Characteristics: Radial 1X, 2X, and 3X peaks.

The spectrum shows vibration components at 1X, 2X, and 3X, but typically no other harmonics. In severe cases, a 0.5X peak may also appear. Phase is also used to assist in identifying this fault. A 180-degree phase difference exists between the bearing and the foundation.

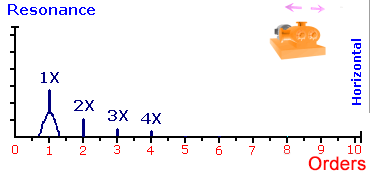

10. Resonance

Characteristics: Typically, only one direction in the spectrum exhibits a “peak.”

Resonance occurs when the excitation frequency matches the machine's natural frequency. The natural frequency refers to the frequency at which a structure vibrates under external driving forces. Along a single axis, a high-amplitude peak exists at the resonance peak. For example, when a pump impeller passes through a resonance peak at 6X frequency, vibration intensification occurs only in the horizontal direction. If the excitation frequency is increased (or decreased) to eliminate resonance, the amplitude will significantly decrease.

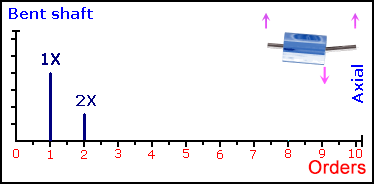

11.Shaft bending

Characteristics: Axial 1X peak.

Shaft deflection causes high-intensity axial 1X vibration. If deflection occurs near the shaft center, the dominant peak typically appears at 1X; if near the coupling, a 2X peak may also appear. Axial, vertical, and horizontal measurements often yield 1X and 2X peaks, but axial measurement is critical here. Phase measurements are highly useful for diagnosing shaft deflection faults. The phase difference between the two ends measured axially at 1X is 180 degrees. (This does not occur in horizontal or vertical measurements.)

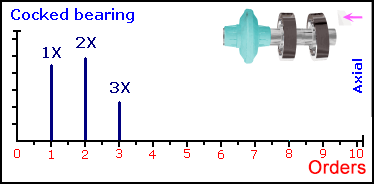

12. Bearing warping

Characteristics: Axial 1X, 2X, and 3X peak frequencies.

Bearing runout, a form of misalignment, produces noticeable axial vibration. Peak frequencies typically occur at 1X, 2X, and 3X. When inspecting suspended pumps or fans, strong axial vibration may be mistaken for misalignment or imbalance. However, peaks at 2X and 3X indicate a higher likelihood of bearing runout than imbalance.

13. Sliding Bearing Clearance Issues

Characteristics: 1X Harmonic

When sliding bearings exhibit clearance issues, the spectral characteristics closely resemble rotational looseness. A strong harmonic will appear at the 1X frequency, with vertical axial vibrations typically exceeding horizontal vibrations in most cases. In more severe instances, half-order or even one-third-order harmonics may also appear in the spectrum.

14. Oil Film Vortex

Characteristics: Radial peaks at 0.38-0.48X.

When oil film vortex action occurs, high-intensity vibration appears between 0.38X and 0.48X. Peak values never occur precisely at 0.5X but instead manifest at slightly lower frequencies. Vortex-induced vibration arises from excessive clearance and slight radial loads, which form an oil film causing the journal to vibrate at less than 0.5 times the rotational speed within the bearing. (e.g., oil film vortex-induced vibration in the turbine-end bearing of Unit A turbine generator at Shanghai Chunxiao Platform)

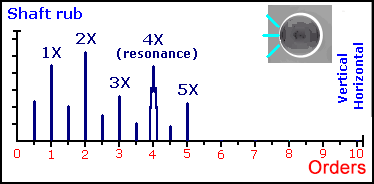

15. Rotor Friction

Characteristics: Radial 1X harmonic (with 0.5X harmonic present in severe cases)

Friction exhibits characteristics similar to rotational looseness: 1X harmonic and 0.5X harmonic. Friction may also induce one or more resonances (occurring at 4X in the example provided).

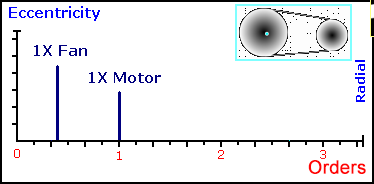

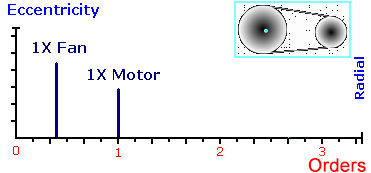

16.Eccentricity

Characteristics: Radial 1X peak (in both horizontal and vertical directions)

Eccentricity occurs when the rotational center of a rotating component (such as gears, bearings, or rotors) is separated from its geometric centerline. An eccentric rotor/bearing generates a high-intensity radial 1X component, particularly in the direction parallel to the rotor/gear. This phenomenon is highly common and resembles an imbalance condition.

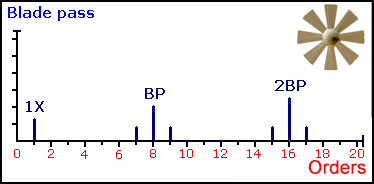

17. Blade Failure

Characteristic: Peak at blade passing frequency

All pumps, fans, and compressors typically exhibit a peak at their blade passing frequency. This frequency equals the number of blades multiplied by the shaft speed. If the clearance between blades and the fixed diffuser is not maintained uniformly, the peak will also increase. It may also be caused by flow channel blockage.

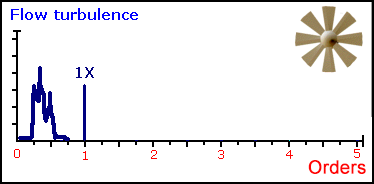

18.Turbulence

Characteristics: Random vibration ranging from 50 to 2000 cycles per minute (CPM).

Turbulence arises from variations in air velocity or pressure passing through fans/blowers. This phenomenon generates low-frequency random vibration, typically occurring within the frequency range of 50 to 2000 CPM.

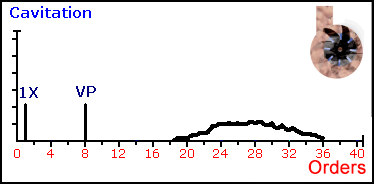

19.Air Cavity

Characteristics: High-frequency “noise.”

Cavitation typically produces random high-frequency vibrations or “noise.” Peak-and-valley patterns are often observable in the frequency spectrum. Cavitation usually results from insufficient suction pressure (such as low inlet pressure). The sound resembles grit inside the pump.

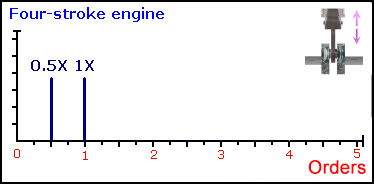

20. Reciprocating machinery

Characteristics: Four-stroke engines—peak at 0.5X; two-stroke engines—peak at 1X.

Vibration intensity in reciprocating machinery is typically high. For four-stroke engines, ignition occurs every two revolutions, producing a high-intensity 0.5X peak. Two-stroke engines, such as many diesel engines, ignite with every revolution, resulting in a high-intensity 1X peak.

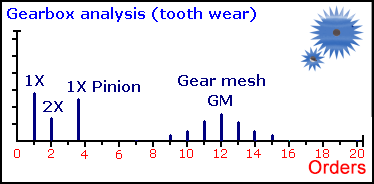

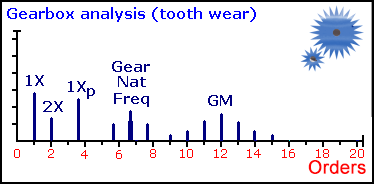

21.Gear meshing

Characteristics: Peak at radial 1x/2x

Peaks typically appear at the shaft rotational frequency and gear meshing frequency, though with low amplitude. A 2x peak may occur, accompanied by sidebands of the shaft rotational frequency near the gear meshing frequency. For spur gears, the primary vibration occurs radially, while for helical gears, it occurs axially.

Time-domain waveform analysis is highly useful for transmissions, as each gear tooth engagement produces a distinct pulse visible in the waveform. Typically, the number of teeth can be determined by examining the time-domain waveform. Characteristically, one pulse is visible per gear revolution, with pulse amplitudes varying in magnitude.

22. Gear wear

Characteristic: 1X edge frequency band near gear meshing frequency

When gear teeth begin to wear, two phenomena occur: First, the amplitude of the edge frequency band at the gear meshing frequency increases, with this amplitude determined by the gear rotational speed. Second, vibrations at the gear's natural frequency emerge. These natural frequency vibrations also generate edge frequency bands, characterized by a broad fundamental frequency.

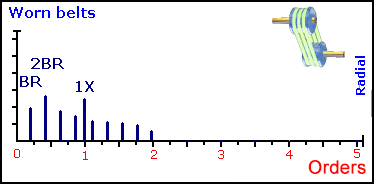

23. Belt wear

Characteristics: Sidebands at the belt speed frequency

If the belt is worn or loose, peaks and harmonics will appear at the belt speed frequency. When two pulleys are present, peaks up to twice the belt speed frequency (2BR) can occur. The primary excitation frequency is the “band frequency” or “baseband pass frequency.” Belt frequency refers to the frequency at which a point on the belt passes a fixed reference point. Typically, the belt frequency is lower than the rotational frequency of any pulley.

24. Belt pulley eccentricity

Characteristics: Radial high-intensity 1X peak

An eccentric pulley generates a strong radial 1X peak, particularly parallel to the belt direction. This phenomenon is highly common and resembles imbalance. It can be detected by removing the belt. Such 1X vibration may also be detected on another pulley.

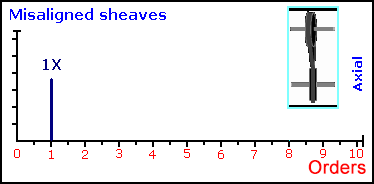

25. Belt pulley misalignment

Characteristics: Radial high-strength 1X wave peaks

If the belt's natural frequency coincides with the rotational speed of the drive pulley or driven pulley, belt resonance can cause high amplitude. The belt's natural frequency can be adjusted by altering the belt length or tension.

Yangzhou Xiyuan Electronic Technology Co.,Ltd.

#77 Yeqiao Road, Liandong U Valley slender West Lake Innovation port, building 10-2,Hanjiang District, Yangzhou,Jiangsu,China

Mobie Phone: +86 180-5105-8377

Tel: +86 514-82885589

Whatsapp:+86 182-6066-6867

Email: sale1@yzxyt.com

Fax: +86 514-82885089