Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Application of Acceleration Vibration Sensors in Escalator Monitoring Systems

1.Industry Background of Escalator Monitoring Systems

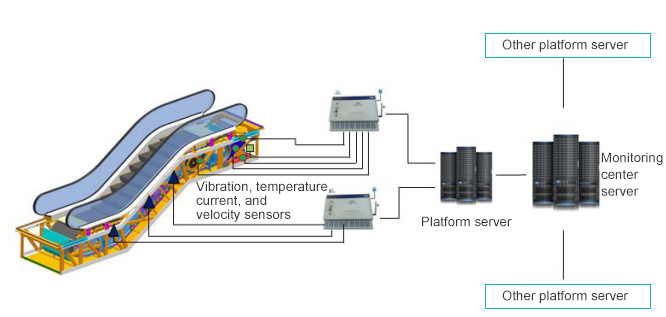

In recent years, China's urban rail transit has experienced rapid development, but it has also witnessed multiple incidents involving significant casualties caused by mechanical failures in escalators. To prevent major accidents, it is necessary to establish an escalator fault monitoring system to promptly detect equipment malfunctions. This solution proposes a health monitoring system for escalators, monitoring vibration, rotational speed, temperature, and current in components such as motors, reducers, drive wheels, and handrails. By analyzing these indicators collectively and establishing a database, the system tracks changes in relevant metrics before equipment failure occurs. This enables early detection of potential hazards and issuance of warnings, preventing major accidents. The system comprises several components: a front-end sensor system, high-precision data acquisition instruments, online monitoring software, and a network transmission system.

2.Monitoring Objectives of the Escalator Monitoring System

Excessive vibration during escalator operation caused by wear issues in bearings, guide rails, and other components may lead to loosening or breaking of fixing bolts over time, potentially resulting in serious accidents such as displacement of the drive unit. Damage to mechanical equipment often develops gradually. In the early stages of failure, no visible signs are apparent. However, once the damage reaches a certain level, catastrophic accidents involving equipment destruction and loss of life may occur suddenly. Yet, early-stage failures—such as bearing or gear wear—are already reflected in vibration signals. Through appropriate data processing, these issues can be detected early. Therefore, sensors can be deployed at critical components to monitor for different types of failures.

3.Functions of Sensors in Escalator Monitoring Systems

(1) Monitoring Targets and Sensors

Vibration Acceleration Sensor: This sensor monitors vibration signals from various mechanical components. When bearings, gears, or rails wear out, or when anchor bolts loosen, the vibration signals change. By extracting characteristic indicators such as peak-to-peak values, kurtosis, rms values, dominant frequency amplitude, and low- or high-frequency amplitude, and combining these with analysis methods like cepstrum and envelope spectrum analysis, it can effectively capture early-stage fault characteristics.

(2) Dynamic Data Acquisition Instrument

This solution employs internationally mainstream 24-bit AD high-precision, high-dynamic-range data acquisition instruments to perform analog-to-digital conversion and preprocessing of sensor signals. This monitoring-type acquisition instrument features windproof, dustproof, moisture-resistant, and strong electromagnetic interference resistance design, capable of withstanding harsh field environments. With multiple escalators present at rail transit platforms, acquisition instruments can be distributed for separate data collection.

4.Xiyuan Electronics Sensor Products for Escalator Monitoring Systems

The A26D is a top-output industrial vibration accelerometer designed for vibration measurement on various rotating machinery or reciprocating equipment. It enables online monitoring, operational maintenance, process monitoring, and protection for main shaft bearings and gearboxes in applications such as fans, pumps, motors, turbines, and compressors.

The A26D industrial vibration accelerometer features a stainless steel housing, laser-welded sealing, dual-layer shielding (isolation), and a waterproof, dustproof, and oil-resistant design. It is suitable for long-term, reliable, and stable operation in various harsh industrial environments. Equipped with an IEPE circuit, it offers isolated floating operation and dual low-impedance voltage outputs, delivering strong anti-interference performance.

AT212 Series Acceleration/Temperature Composite (AT Series):

This series of acceleration sensors features dual outputs for vibration and temperature. Constructed with a stainless steel housing and laser-welded sealing, they offer high reliability. The dual-layer shielding provides strong anti-interference capability, making them suitable for long-term, reliable operation in various harsh environments. They are applied to dual-parameter vibration and temperature monitoring of gears, bearings, and drive shafts in transmission systems for industrial rotating machinery, rail transit, and smart vessels.

XY-G9 Gigabit Network Series Analyzer

1. Built-in 4mA/24V constant current circuit enables direct connection to IEPE-type accelerometers, velocity sensors, force transducers, microphones, and other devices for signal testing and analysis;

2. Voltage signal measurement: Compatible with thermocouples, eddy current sensors, magnetoelectric velocity sensors, strain sensors, and various transmitters (conditioners) for testing and analyzing multiple physical quantities;

3. Optional built-in charge conditioner for connecting piezoelectric sensors, enabling accurate measurement of dynamic pressure and vibration acceleration;

4. 24-bit high-precision A/D conversion with parallel synchronous sampling across all channels, delivering low noise and high accuracy. Real-time communication with computers via Gigabit Ethernet enables continuous sampling rates up to 256 kHz per channel;

5. Optional D/A digital signal source output module generates sine, sweep, random, square wave, and other signals. Integrates with power amplifiers, vibration test tables, accelerometers, and other components to form diverse vibration test systems;

6. Optional optically isolated digital I/O interface module for reading input signals (e.g., encoders, photoelectric switches) and controlling external outputs;

7. Includes user-friendly, feature-rich acquisition and analysis software to configure input types, ranges, sensor sensitivity, sampling rates, etc. Enables real-time data transmission, display, and processing. Utilizes computer hard drives for long-term, uninterrupted multi-channel signal recording.

8. Utilizes Gigabit Ethernet switches for expansion, enabling a single computer to perform parallel synchronous acquisition and analysis of multiple devices. Widely applied in fatigue testing, performance evaluation, and characteristic analysis of various structures across education, research, aerospace, automotive, and rail transportation industries.

XY-U9 Medium-Speed Dynamic Signal Analyzer

1. Built-in 4mA/24V constant current circuit directly connects to IEPE accelerometers, velocity sensors, force transducers, microphones, and other devices for signal testing and analysis;

2. Voltage signal measurement: Compatible with thermocouples, eddy current sensors, magnetoelectric velocity sensors, strain gauges, and various transmitters (conditioners) for testing and analyzing multiple physical quantities;

3. 24-bit high-precision A/D converter with 4/8/16/32-channel parallel synchronous sampling. Maximum sampling rate of 128kHz per channel, featuring low noise and high accuracy;

4. Equipped with user-friendly, feature-rich acquisition and analysis software. Configure parameters such as input type, range, sensor sensitivity, and sampling rate for the dynamic signal analyzer. Enables real-time data transmission, display, and analysis processing. Utilizes computer hard drives for long-term, uninterrupted real-time recording of multi-channel signals.

After long-term monitoring of equipment, operational status data for each period will be continuously accumulated. Based on this historical data, a fitting curve is derived through fitting methods. This curve reflects the trend of data changes, representing the evolution of the equipment's operational status. Typically, as equipment usage time increases, its condition deteriorates due to factors like wear and tear, resulting in progressively higher vibration data. The trend curve enables assessment of the equipment's deterioration rate and predict whether it will reach or exceed the danger threshold within a certain period of time in the future. Trend forecasting allows for proactive identification of potential failures before they occur, enabling timely implementation of appropriate maintenance strategies to achieve predictive maintenance.

Yangzhou Xiyuan Electronic Technology Co.,Ltd.

#77 Yeqiao Road, Liandong U Valley slender West Lake Innovation port, building 10-2,Hanjiang District, Yangzhou,Jiangsu,China

Mobie Phone: +86 180-5105-8377

Tel: +86 514-82885589

Whatsapp:+86 182-6066-6867

Email: sale1@yzxyt.com

Fax: +86 514-82885089